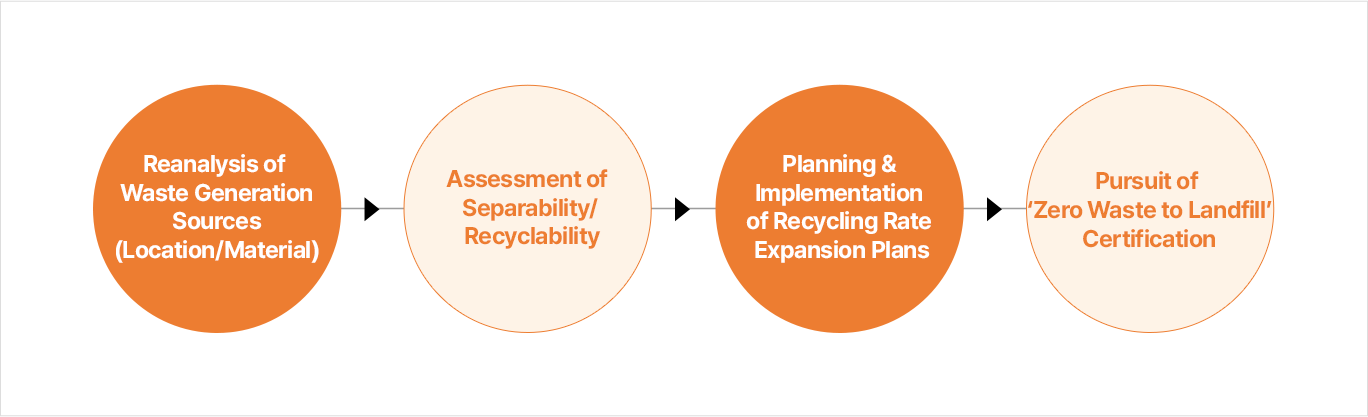

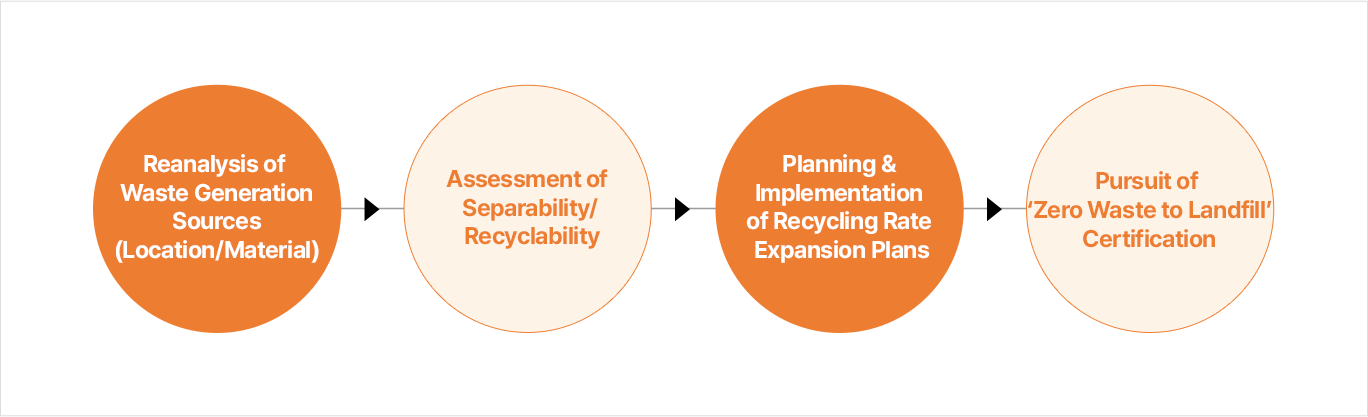

Waste Management

SK bioscience actively promotes the recycling and reuse of resources throughout all stages of product manufacturing and operates a waste management system to prevent environmental pollution. The Company closely monitors waste generation status at each stage of process and tracks the entire lifecycle—from generation to final disposal—to minimize environmental impact.

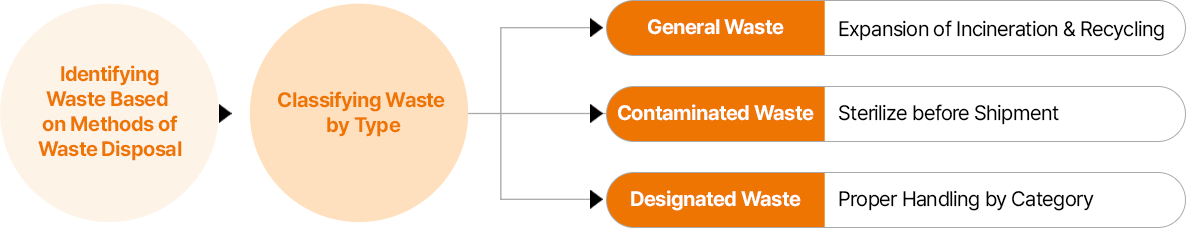

Especially, wastes that pose a potential risks to human health or the environment are separately sorted and sterilized prior to disposal to neutralize harmful effects. Designated wastes are managed in strict compliance with relevant regulations and are handled separately through authorized external contractors. General wastes are legally disposed of and further handled for recycling by partnering with certified recycling vendors.

To support systematic waste management, data on waste generation is regularly collected and reported. In 2025, SK bioscience plans to initiate various recycling projects to further improve its recycling rate.

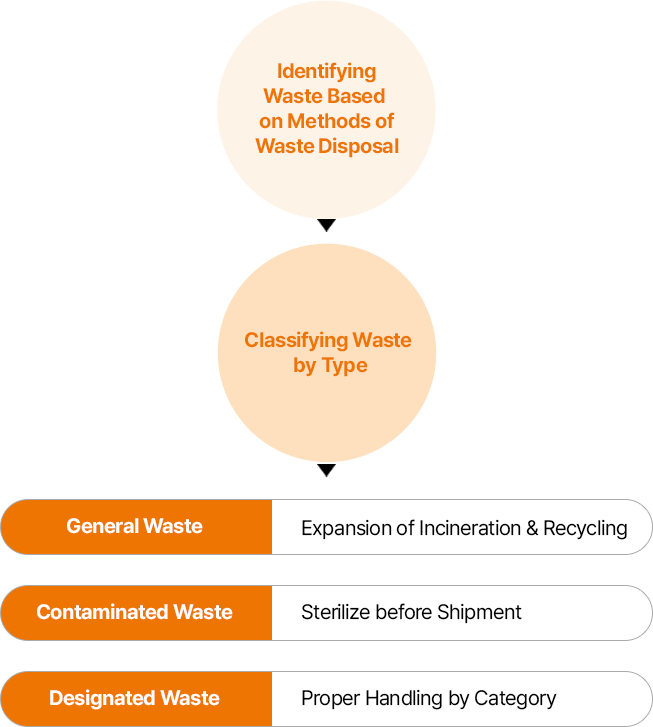

Process Monitoring and Waste Classification Process

- 처리 유형에 따른 폐기물 식별

- 유형별 폐기물 분류

-

- 일반 폐기물

- 업체를 통한 재활용

- 오염 우려 폐기물

- 반출 전 멸균

- 지정 폐기물

- 업체를 통한 별도 배출

Since 2023, SK bioscience has implemented annual internal audits of waste management contractors handling onsite waste. These audits assess the compliance of waste processing and the adequacy of treatment facilities. The findings are quantified based on our own criteria and used to decide contract renewals or to mandate corrective actions. Additionally, we continuously update audit checklist through monitoring of laws and regulations for effective and transparent management.

| Target | No. of Contractors | Inspection Frequency | Inspection Results |

|---|---|---|---|

| Waste Disposal Contractors | 16 (8 in Andong/8 in Pangyo) |

At least once per year | No notable issues detected (As of January 2025) |

Key Inspection Items

- 1Consistency between licensed waste processing facilities and those in operation (including storage and prevention facilities)

- 2Possession of adequate processing capacity (including facilities, vehicles, and personnel)

- 3Compliance with permitted storage volumes and storage periods

- 4Implementation of safety measures (such as the use of protective gear, safety devices, and workplace lighting)

- 5Status of complaints and administrative actions

- 6Compliance with legal processing, including any re-delegation to other companies

Hazardous Chemicals Management

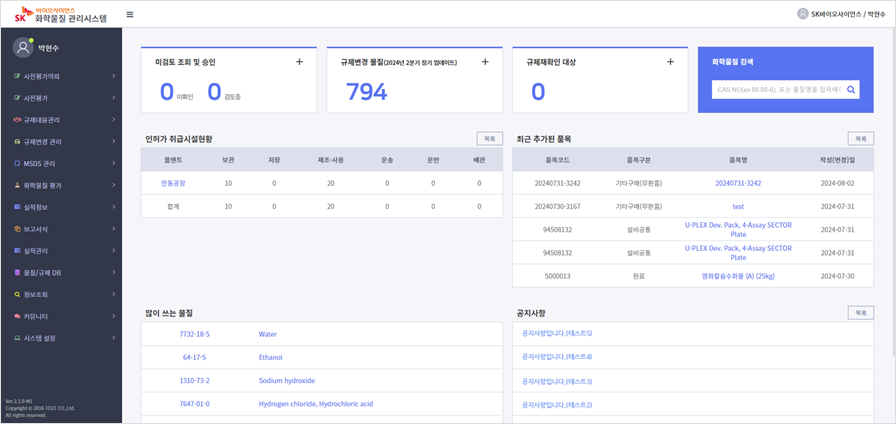

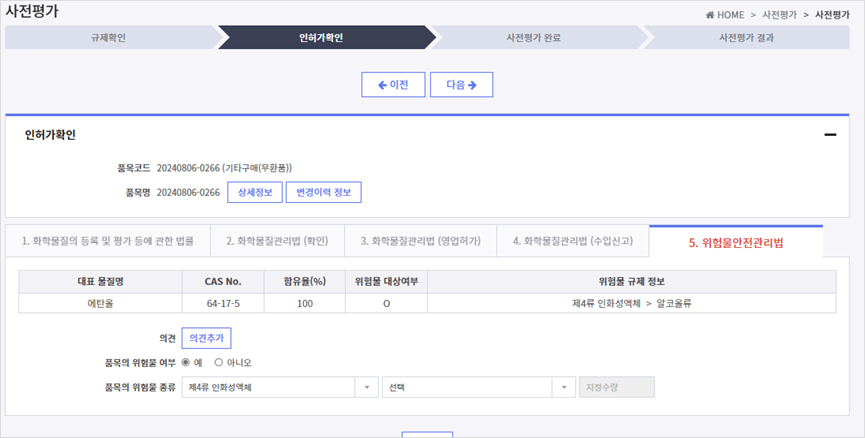

In July 2024, SK bioscience introduced the Chemical Management System (CMS) to comply with chemical-related laws and regulations and to proactively respond to them, as the importance of managing hazardous substances is growing due to strengthening global regulations. We conduct pre-arrival assessments for all chemicals and manage the entire process from usage to storage and disposal to prevent accidents and diseases that could threaten the safety of workers and local communities.

In addition, chemical product information is managed in accordance with the latest GHS-MSDS1) standards, based on which appropriate protective equipment is selected, special medical examinations are conducted, and work environment measures are taken. In the case of imported chemicals, the purchase is made after completing appropriate licensing procedures through preliminary review by a designated department, and hazardous chemicals are handled safely in appropriate facilities such as limited exhaust systems. At facilities handling hazardous chemicals, managers are appointed to conduct regular self-inspections and monitoring. We will continue to strengthen the safe handling of chemicals and compliance with laws and regulations through CMS-based monitoring, and strive to prevent accidents for the safety of employees and the environment.

IDT Biologika (hereinafter IDT) imports chemical substances within the EU, and these substances must be registered in accordance with the Registration, Evaluation, Authorization and restriction of Chemicals (REACH)2) Regulation. For hazardous substances used at the site, IDT has established operating procedures to ensure their safe handling. Additionally, a Hazardous Substance Officer regularly inspects the site and implements preventive safety measures to identify and mitigate potential risks or irregularities. Before any work begins, a risk assessment specific to the area or activity is conducted. Regular training is also provided to all employees to minimize the risk of accidents while handling hazardous substances.

- 1) GHS MSDS : Globally Harmonized System of Classification and Labelling of Chemicals Material Safety Data Sheet

- 2) REACH (Registration, Evaluation, Authorization and restriction of Chemicals Regulation): EU’s regulation for chemical safety, placing responsibility on companies to assess and manage risks to health and environment.

CMS Main Screen

CMS Pre-assessment Screen

Hazardous Chemicals Safety Training

SK bioscience operates a training system to raise employees' awareness of the dangers of chemicals and their safe handling. We include key chemicals in new hire training and regular safety and health training courses for all employees. We also provide separate training on MSDS to inform the potential dangers of introducing new chemical substances. Moreover, we train chemical handlers by setting up standards for wearing protective equipment against hazardous chemicals. In 2024, we went all out to prevent related accidents by conducting special safety training for these handlers.

Air Pollutant Management

To reduce air pollutants generated by fossil fuels, SK bioscience has replaced industrial boiler fuels with LNG. We have implemented measures to manage air pollutants at the generation stage, including the addition of a number control function to operate the boilers sequentially based on steam requirements. Furthermore, we conduct regular measurements to ensure compliance with emission limits.

Andong L HOUSE uses eco-friendly refrigerants that minimize ozone-depleting substances generated during refrigerator operation. In addition, to manage exhaust gas within the workplace, we measure the quality of air that is coming from outside to maintain a fresh air percentage of 30% or higher compared with the standards. We control indoor pollutants and prevent the infiltration of pollutants by operating independent and local heating, ventilation, air conditioning (HVAC) equipment. This is done not only to protect both the atmospheric environment and the respiratory health of employees within the workplace.

Water Resources Management

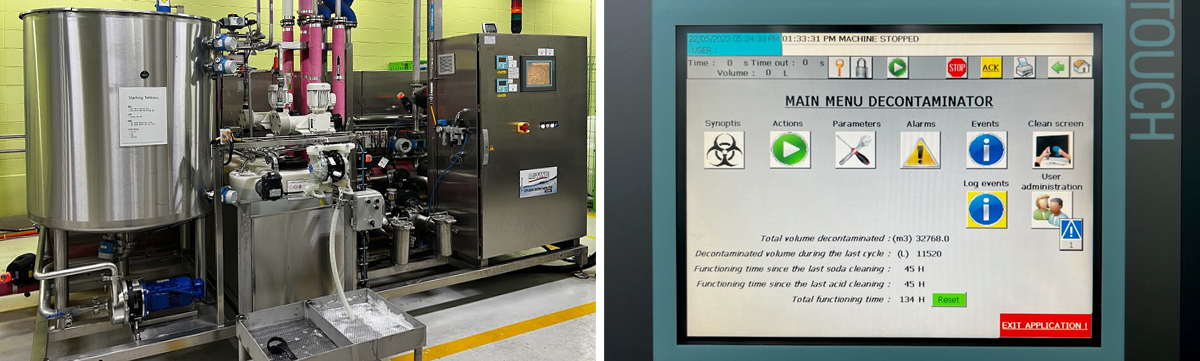

SK bioscience’s water resources management minimizes wastewater generation and reduces water consumption. We utilize in-house Biokill system to effectively reduce water pollution risk, and minimize contamination during discharge by removing biological hazards that may arise from the process, and by controlling the pH level and sterilization before discharge.

The wastewater from Andong L HOUSE is sent to a wastewater treatment facility, where it is regularly monitored to ensure that its discharge remains below the inflow concentration level approved by Andong City. Additionally, we establish wastewater reduction plans based on monthly emission data, and from 2023, we installed additional wastewater meters to precisely manage data by source.

We also work to reduce our water usage, by recycling water used in the process, installing rainwater tanks in the plant, and introducing green vegetation to minimize water use. The usage and discharge of water are measured using a flowmeter, with the figures recorded twice a day. Additionally, Andong L HOUSE outsources the treatment of all wastewater to a public wastewater treatment facility within the Gyeongsangbuk-do Bio Industry Complex. This facility adheres to stricter standards than the statutory raw wastewater discharge concentration limits, ensuring safer and more effective treatment.

Water Pollutant Management System

Biodiversity Conservation

SK bioscience deeply recognizes the value of biodiversity and the importance of preserving ecosystems, and integrate environmental conservation topic into regular training programs for employees. We also protect the natural environment and ecosystems in the vicinity by preserving the original form as much as possible when expanding business sites.

In 2024, we selected the 'Phygasia fulvipennis' as a protected species through a biodiversity survey near Andong L HOUSE, and ran employee-participating clean-up campaign to preserve the habitat of the species. In 2025, we are planning to organize protection activities for nationally designated and protected wildlife species living in Andong. Meanwhile, our new global R&PD Center in Songdo plans to minimize water pollution and reduce the impact on biodiveristy by treating wastewater generated during R&D and discharging it into the West Sea through the Songdo Sewage Terminal Treatment Plant. SK bioscience will continue to coexist with local ecosystems, practice biodiversity conservation throughout its business activities, and create sustainable environmental values with local communities.

IDT is also committed to protecting and supporting biodiversity by creating habitats for various species of plants and animals, helping to preserve the natural ecosystem. Since 2022, the northern section of the Biopharmapark has hosted a ‘bee hotel’, which is maintained by an IDT employee who is also an amateur beekeeper. In collaboration with TEW Service which is an affiliated company of IDT, four bee colonies have been established. The bees benefit from optimal feeding conditions throughout the year in the Biopharmapark, thereby contributing to the area's biodiversity. IDT also made a donation to the Klix3 project, a research initiative focused on climate neutrality and funded by the Federal Ministry for Economic Affairs and Climate Action, reinforcing the company's commitment to environmental protection. Additionally, IDT employees participated in environmental protection activities organized by BUND - Friends of the Earth Germany, incorporating these initiatives into team-building efforts.